Building a new substation or retrofitting the old one is a complex process full of design and engineering tasks to be worked on. The main steps in substation design and engineering are as follows:

Step 1 – switching system

Selection of a substation switching system: ring bus, breaker-and-a-half, etc. based on reliability requirements.

Step 2 – key plan, location of components

Preparation of a key plan which should show the location of all components of a substation and their interconnections, as well as steel structures, control house, fire walls, driveways, fence and property line.

Step 3 – equipment selection and ordering

Selection and ordering of equipment, which is usually done in a utility company by a designated group of equipment experts.

They specify transformers, breakers, etc., request bids form approved vendors, evaluate the bids, place the order with a winning bidder, and participate in testing and commissioning of equipment.

Step 4 – engineering support

Engineering support for licensing and permitting which includes preparation of necessary drawings sealed by professional engineers, testifying at public hearings at the municipalities where a new substation is planned to be built, ordering of noise studies and selecting means of noise mitigation if needed.

Step 5 – civil and structural design

Civil and structural design which includes:

1. Pile design

2. Foundations

3. Steel structures

4. Control house

Step 6 – electrical layout design

Electrical layout design which includes:

1. Positioning of equipment

2. Bus design

3. Design of manhole and conduit system

4. Design of auxiliary A.C. power system

5. Selection of D.C. batteries and battery chargers

6. Layout of control house

7. Grounding and lightning protection design

Step 7 – relay protection, SCADA

Control design which includes:

1. Relay protection and instrumentation system schematics and wiring diagrams

2. Relay racks or panels

3. Remote control and metering (SCADA – system control and data acquisition)

Step 8

Construction support which includes a resolution of technical problems discovered during construction, ordering of additional materials, etc.

Further details of major equipment

Because selection of the major equipment is one of the most critical tasks in substation engineering, there are a lot of details. These are just the part of some major equipment ratings:

Power transformer ratings

• Capacity including overload capability

• Cooling class

• Frequency

• Primary and secondary voltage

• Phase relation between primary and secondary voltages

• BIL for both high and low voltage sides

• Voltage regulation requirements: load and no-load taps

• Transformer impedance

• Sound level

Circuit breaker ratings

• Rated maximum voltage

• Rated continuous current

• BIL

• Rated short circuit current

• Interrupting time

• Rated frequency

Current transformer (CT) ratings

• BIL

• Rated current

• Rated frequency

• Number of taps and ratio for each tap

• Accuracy class

• Type (bushing CT, free standing, etc.)

Voltage transformer (VT) ratings

• Rated voltage factor

• Rated primary voltage (Up)

• Rated secondary voltage

• Accuracy power

• Accuracy class

• Voltage ratio error

• Phase or phase displacement error

• Rated thermal limiting output

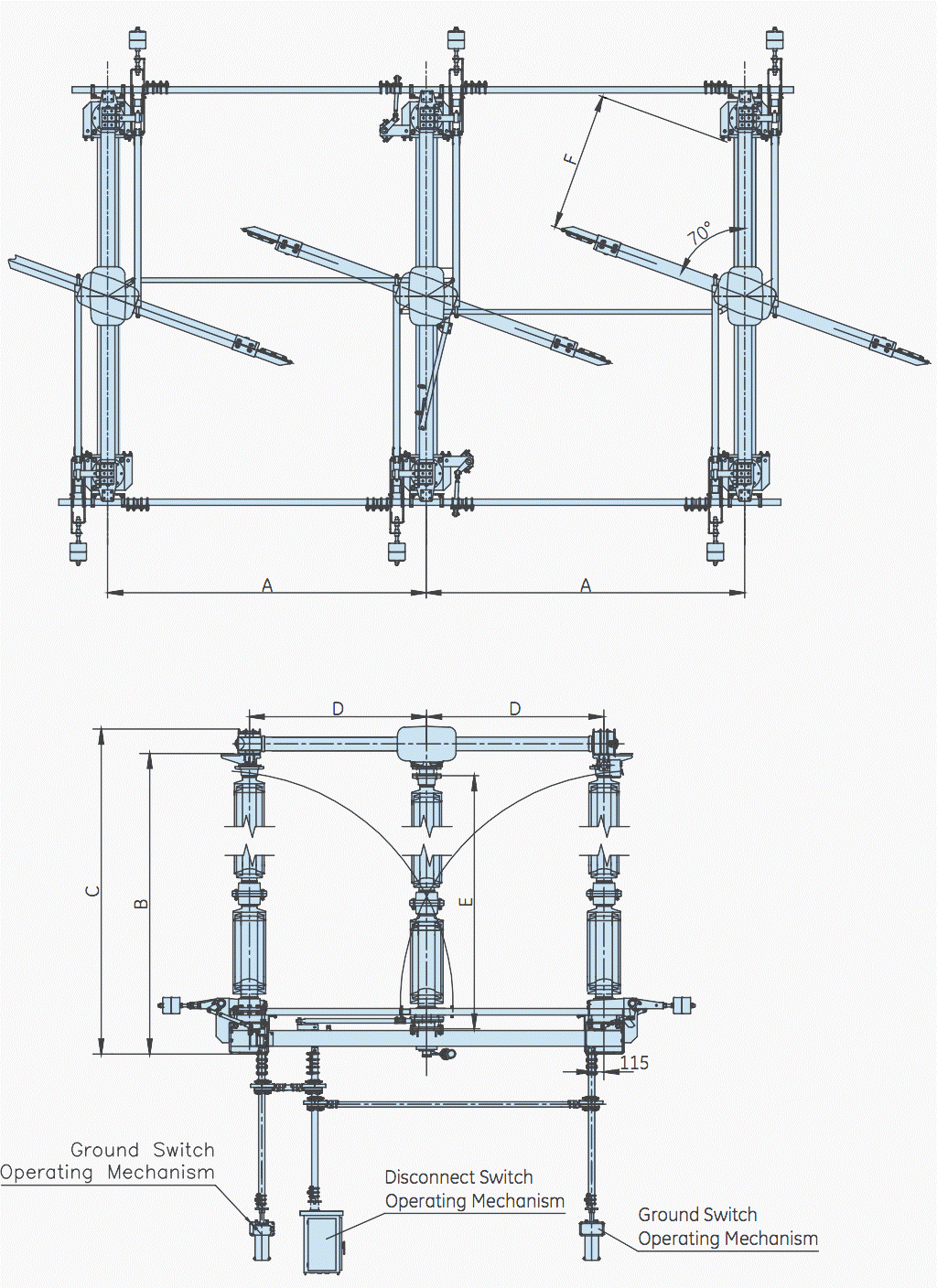

Disconnect switch ratings

• Rated voltage

• Rated frequency

• Rated current

• Rated short-time withstand current and duration

• Rated peak withstand current

• Rated short-time power frequency withstand voltage (rms) – To earth between breaks

• Rated lightning impulse withstand voltage (peak) – To earth between breaks

• Rated busbar transferring current

• Type of motor operation mechanism

• Switching capacitive current

• Switching inductive current

• Switching busbar transferring current Bus-transfer current