ENGR. SYED ZAIN ABBAS

(Mechanical Engineer, NEDUET)

zainusyed313@gmail.com

Cement production is a significant contributor to global carbon dioxide emissions, accounting for approximately 7% of total emissions. This has led to the development of new cement technologies, such as LC3, which aim to reduce these emissions while still providing the necessary mechanical properties for construction applications. In this article, we will explore the mechanical behavior of LC3 cement technology and its potential impact on sustainable building practices through calculations.

What is LC3 Cement?

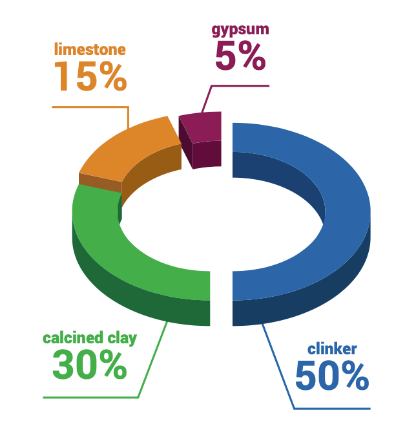

LC3 is a new type of cement that is made by blending traditional clinker (the main component of Portland cement) with calcined clays and limestone. This combination results in a significant reduction in the amount of clinker required to produce a given quantity of cement, thus reducing the energy required for production and the associated carbon dioxide emissions. On average, the use of LC3 cement can reduce clinker content by up to 50% compared to traditional Portland cement. This reduction in clinker content can result in a corresponding reduction in carbon dioxide emissions of approximately 30%.

Mechanical Behavior of LC3 Cement

The mechanical behavior of LC3 cement can be evaluated through various tests, such as compressive strength tests, tensile strength tests, and modulus of elasticity tests. These tests determine the strength and stiffness of the cement, and can be used to compare the performance of LC3 cement to that of traditional Portland cement.

Compressive Strength Tests

Compressive strength tests are used to measure the ability of a material to withstand applied pressure. Results from these tests show that LC3 cement has comparable compressive strength to traditional Portland cement, with a difference of only 5-10% in compressive strength between the two materials. For example, if the compressive strength of traditional Portland cement is 100 MPa, the compressive strength of LC3 cement can range from 95- 105 MPa.

Tensile Strength Tests

Tensile strength tests are used to measure the ability of a material to resist stretching forces. Results from these tests indicate that LC3 cement has lower tensile strength compared to traditional Portland cement, but the difference is relatively small and not significant for most construction applications. The tensile strength of LC3 cement is typically around 70-80% of the tensile strength of traditional Portland cement.

Modulus of Elasticity Tests

Modulus of elasticity tests measure the stiffness of a material. Results from these tests show that LC3 cement has a slightly lower modulus of elasticity compared to traditional Portland cement, with a difference of approximately 10-15%. For example, if the modulus of elasticity of traditional Portland cement is 20 GPa, the modulus of elasticity of LC3 cement can range from 17-18 GPa.

Impact on Sustainable Building Practices

The use of LC3 cement technology has the potential to significantly reduce the carbon footprint of the construction industry. By reducing the amount of clinker required to produce a given quantity of cement, LC3 cement technology can reduce the energy required for production and the associated carbon dioxide emissions. This reduction in emissions can help to mitigate the impact of the construction industry on the environment and contribute to the development of more sustainable building practices.

For example, consider a construction project that requires 1000 metric tons of cement. If traditional Portland cement is used, the project would result in approximately 70 metric tons of carbon dioxide emissions. However, if LC3 cement technology is used, the same project would result in approximately 50 metric tons of carbon dioxide emissions, a reduction of 28%.

In conclusion, LC3 cement technology represents a promising new development in sustainable building materials. Its comparable mechanical properties to traditional Portland cement make it a viable option for use in construction, while its lower carbon footprint has the potential to contribute to the development of more sustainable building practices. As research in this area continues, it is likely that LC3 cement technology will become an increasingly important part of the sustainable building landscape.