A new frontier in cooling technology

Hafiz Ozair Ahmada , Muhammad Sajid Kamran

a)Department of Mechanical Engineering, University of Engineering and Technology, Lahore, 54890, Pakistan.

b)School of Engineering and Materials Science, Queen Mary, University of London, Mile End Road, London E1 4NS, UK

*Corresponding author: m.s.kamran@uet.edu.pk

Magnetic refrigeration is a modern, energy efficient and environmentally friendly cooling technique based on the magnetocaloric effect of magnetic materials. It has been employed to achieve very low temperatures and it does not involve any harmful ozone depleting gases as in the case of conventional vapour compression refrigeration systems. Active magnetic regenerative (AMR) systems have been used to enhance the heating/cooling performance of magnetic refrigerators. This research work presents a review and analysis of the major experimental and numerical advancements made in the field of magnetic refrigeration.

Key words: Magnetic refrigeration, Experimental research, Numerical modelling, Magnetocaloric material, Performance indicators.

Introduction

Magnetic refrigeration is a newly developed and emerging cooling technique which is based on magnetocaloric effect of magnetic materials to produce cooling/heating. The magnetocaloric effect of magnetic materials was firstly noticed by Warburg in 1881 (Bohigas et al. [1]). He observed that the temperature of iron piece increased when it was brought to the external magnetic field and it reduced when the piece was taken away from the magnetic field. The materials which possess this property are known as the Magnetocaloric materials (MCMs). As compared to vapour compression systems, magnetic refrigeration is an environmental friendly and energy efficient cooling technology (Gschneidner Jr and Pecharsky [2]). Very low ranges of temperatures have been achieved by using the cooling technology of magnetic refrigeration. It gives more theoretical cooling efficiency when compared with conventional vapour compression refrigeration systems (Zhang et al. [3]).

Working Principle of Magnetic Refrigerator

A typical magnetic refrigeration cycle usually consists of four major stages of processes which are shown below in Fig. 1 and described in the following; (a) magnetization: the magnetic field strength is increased causing magnetic entropy to decrease which further increases the temperature of MCM; (b) cold blow: some heat transfer fluid is employed to absorb the heat from the MCM to cool it down to the ambient temperature; (c) demagnetization: the magnetic field intensity is decreased causing magnetic entropy to increase which further lowers the temperature of MCM; (d) hot blow: again a heat transfer fluid is used to reject the heat to the MCM increasing its temperature and thus the cycle goes on.

Fig. 1 Stages of magnetic refrigeration cycle (taken from Franco et al. [4])

Magnetic refrigerator usually consists of the following major components as shown below in Fig. 2: (1) Regenerator: which works as a solid refrigerant e.g. Gadolinium; (2) Working fluid/heat transfer fluid: transfers the heat to/from regenerator and heat exchangers e.g. water; (3) Magnetic field source: provides required magnetic field strength; (4) Hot and Cold end heat exchangers; (6) Hydraulic system: circulates the heat transfer fluid in the system.

Fig. 2 Components of a magnetic refrigerator (taken from Kamran et al. [5])

Experimental research

This section covers the major experimental work that has been carried out to improve the cooling performance of magnetic refrigerators. Very first magnetic cooling system was developed by Brown in 1976 (Brown [6]). He used an electromagnet to generate the required magnetic field with an intensity of 7T. Gadolinium plates were used as the refrigerant and water with alcohol was employed as the heat transfer fluid. This system obtained a temperature span of 47K after 50 operating cycles. A team from the “Polytechnic University of Catalonia in Barcelona” developed a magnetic cooling mechanism as shown below in Fig. 3 (Allab [7]). A disk with a gadolinium ribbon was used as the magnetocaloric material. The disk rotated in the magnetic field which provided the magnetization and demagnetization. They achieved a temperature span of 1.6K and 5K with a magnetic field strength of 0.3T and 0.95T respectively. The achieved temperature span was not much higher but the device was important in the aspect that it showed the feasibility of using permanent magnets to produce the desired magnetic field.

Fig. 3 Magnetic system developed in Spain (taken from Bohigas et al. [1])

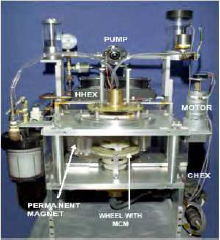

“The Astronautics Corporation in Madison” developed an active magnetic regenerative magnetic refrigeration system, as shown below in Fig. 4, having a wheel which consisted of 6 beds of gadolinium powder (Engelbrecht et al. [8]). The wheel rotated in a magnetic field of 1.5T. They achieved a temperature span of 4K and 20K with an operating frequency of 0.16Hz and 2.0Hz respectively.

Fig. 4 Magnetic system developed by Astronautics Corporation in Madison (taken from Zimm et al. [9])

In the same way, many other experimental setups of magnetic cooling systems have recently been developed including a prototype developed by G2ELab (Clot et al. [10]) and the magnetic refrigeration system using Halbach array of magnets developed by Tura and Rowe [11] in 2007.

Numerical Modelling

The mathematical or numerical approach along with the experimental has also been used to investigate, optimize and improve the performance of magnetic refrigeration systems. Nielsen et al. [12] have reviewed the important numerical models of room temperature AMR devices developed till 2010. The effect of various parameters like magnetocaloric effect (MCE), governing equations, profiles of magnetic field, fluid flow behaviour and thermal conduction on the performance of room temperature AMR devices have been studied and analysed in detail. Tušek et al. [13] developed a time dependent, 1D numerical model to analyse the operation of AMR refrigerator. The software package MATLAB has been employed to solve coupled equations for magnetocaloric material and the heat transfer fluid. The numerical model can be used to analyse various parameters like magnetic field strength, layered and single AMRs. Lei et al. [14] presented the simulations for multi-layered AMR using La(Fe,Mn,Si)13Hy. A very careful selection of working temperature and number of layers is required because the said material gives a sharp and large isothermal change in entropy. Fig. 5 shows the variation of cooling power with the number of layers of MCM. The authors have used a one dimensional numerical model to determine the influence of temperature span, working temperature and number of layers.

Fig. 5 Cooling power vs Number of layers of MCM (taken from Lei et al. [14]).

Other than the above mentioned, many other numerical models of magnetic refrigerators have recently been developed by the researchers including the numerical models of Li et al. [15], Vuarnoz and Kawanami [16], Nikkola et al. [17] and Burdyny et al. [18].

Performance indicators

Magnetic refrigeration produces a cooling (refrigeration) effect in a certain area. Modern magnetic refrigerators employee an active magnetic regenerator (AMR) which can store a certain amount of heat and thus enhances the cooling/heating effect by increasing the heat transfer taking place between the MCM and heat transfer fluid.

Various parameters can be observed to quantify the cooling and overall performance of a magnetic refrigerator. Temperature span or temperature difference achieved between the hot and cold ends of the regenerator is one of the most important parameter to measure the cooling effect being produced by the refrigerator. Cooling capacity is directly related to the temperature span of the regenerator. The input power which is required to circulate the heat transfer fluid in the entire system also plays an important role while determining the overall performance of a magnetic refrigerator. The cooling capacity per unit pumping power is usually used as an indicator of COP to determine the overall performance of magnetic refrigerator. Kamran et al. [5] have used all these performance indicators to numerically determine the cooling and overall performance of a micro-channel AMR magnetic refrigerator using gadolinium and water as the MCM and heat transfer fluid respectively.

Important performance parameters

There are various parameters which significantly affect the cooling characteristics and overall performance of magnetic refrigerator. They mainly include; (1) magnetic field intensity; (2) type, shape and size of magnetocaloric material; (3) porosity of magnetocaloric material; (4) type of heat transfer fluid; (5) mass flow rate of heat transfer fluid shown by utilization factor (φ); (6) operating frequency of the magnetic cycle.

Kamran et al. [5] have investigated the effects of the above mentioned parameters on the cooling characteristics of a micro-channel AMR refrigerator. Fig. 6 presents the effects of operating frequency and mass flow rate (utilization factor) on the cooling capacity of micro-channel AMR.

Fig. 6 Variation of cooling capacity of micro-channel AMR with; (a) Utilization factor; (b) Operating frequency

Conclusion

This research work highlights the significance of magnetic refrigeration as a newly emerging cooling technology. We have presented the basic working principle of a typical magnetic refrigerator with major experimental and numerical research that has been carried out to investigate and improve the cooling performance of magnetic refrigerator. This paper also described the important performance parameters and indicators which are used to quantify the performance a magnetic refrigerator. There is a lot of room for improvement and performance optimization of magnetic refrigerator and research is being carried out in this field.

List of figure captions

Fig. 1 Stages of magnetic refrigeration cycle (taken from Franco et al. [4])

Fig. 2 Components of a magnetic refrigerator (taken from Kamran et al. [5])

Fig. 3 Magnetic system developed in Spain (taken from Bohigas et al. [1])

Fig. 4 Magnetic system developed by Astronautics Corporation in Madison (taken from Zimm et al. [9])

Fig. 5 Cooling power vs Number of layers of MCM (taken from Lei et al. [14]).

References

[1] Bohigas, X., E. Molins, A. Roig, J. Tejada, and X. Zhang, Room-temperature magnetic refrigerator using permanent magnets. IEEE Transactions on Magnetics, 2000. 36(3): p. 538-544.

[2] Gschneidner Jr, K.A. and V.K. Pecharsky, Thirty years of near room temperature magnetic cooling: Where we are today and future prospects. International Journal of Refrigeration, 2008. 31(6): p. 945-961.

[3] Zhang, H., J. Shen, M.Q. Gong, and J.F. Wu, Cooling performance of a room-temperature magnetic refrigerator prototype. Journal of Applied Physics, 2010. 107(9).

[4] Franco, V., J. Blázquez, B. Ingale, and A. Conde, The magnetocaloric effect and magnetic refrigeration near room temperature: materials and models. Materials Research, 2012. 42(1): p. 305.

[5] Kamran, M.S., J. Sun, Y.B. Tang, Y.G. Chen, J.H. Wu, and H.S. Wang, Numerical investigation of room temperature magnetic refrigerator using microchannel regenerators. Applied Thermal Engineering, 2016. 102: p. 1126-1140.

[6] Brown, G., Magnetic heat pumping near room temperature. Journal of Applied Physics, 1976. 47(8): p. 3673-3680.

[7] Allab, F., ETUDE ET CONCEPTION D’UN DISPOSITIF DE REFRIGERATION MAGNETIQUE BASE SUR L’EFFET MAGNETOCALORIQUE GEANT, 2008, Institut National Polytechnique de Grenoble-INPG.

[8] Engelbrecht, K., G. Nellis, S. Klein, and A. Boeder. Modeling active magnetic regenerative refrigeration systems. in Proceedings of 1st International conference on Magnetic Refrigeration at room temperature. 2005.

[9] Zimm, C., J. Auringer, A. Boeder, J. Chell, S. Russek, and A. Sternberg. Design and initial performance of a magnetic refrigerator with a rotating permanent magnet. in Proceedings of the 2nd International conference of magnetic refrigeration at room temperature, Portoroz, Slovenia. 2007.

[10] Clot, P., D. Viallet, A. Kedous-Lebouc, J. Fournier, J. Yonnet, and F. Allab. A permanent magnet based device for active magnetic regenerative refrigeration. in Magnetics Conference, 2003. INTERMAG 2003. IEEE International. 2003. IEEE.

[11] Tura, A. and A. Rowe. Design and testing of a permanent magnet magnetic refrigerator. in Proceedings of the 2nd international conference of magnetic refrigeration at room temperature, Portoroz, Slovenia. 2007.

[12] Nielsen, K.K., J. Tusek, K. Engelbrecht, S. Schopfer, A. Kitanovski, C.R.H. Bahl, A. Smith, N. Pryds, and A. Poredos, Review on numerical modeling of active magnetic regenerators for room temperature applications. International Journal of Refrigeration, 2011. 34(3): p. 603-616.

[13] Tušek, J., A. Kitanovski, I. Prebil, and A. Poredoš, Dynamic operation of an active magnetic regenerator (AMR): Numerical optimization of a packed-bed AMR. International Journal of Refrigeration, 2011. 34(6): p. 1507-1517.

[14] Lei, T., K.K. Nielsen, K. Engelbrecht, C.R. Bahl, H.N. Bez, and C.T. Veje, Sensitivity study of multi-layer active magnetic regenerators using first order magnetocaloric material La (Fe, Mn, Si) 13Hy. Journal of Applied Physics, 2015. 118(1): p. 014903.

[15] Li, J., T. Numazawa, H. Nakagome, and K. Matsumoto, Numerical modeling on a reciprocating active magnetic regenerator refrigeration in room temperature. Cryogenics, 2011. 51(6): p. 347-352.

[16] Vuarnoz, D. and T. Kawanami, Numerical analysis of a reciprocating active magnetic regenerator made of gadolinium wires. Applied Thermal Engineering, 2012. 37: p. 388-395.

[17] Nikkola, P., C. Mahmed, M. Balli, and O. Sari, 1D model of an active magnetic regenerator. International Journal of Refrigeration, 2014. 37: p. 43-50.

[18] Burdyny, T., A. Ruebsaat-Trott, and A. Rowe, Performance modeling of AMR refrigerators. International Journal of Refrigeration, 2014. 37: p. 51-62.