Engr. Zain Abbas Hasnain , Mechanical Engineer, NED

Artificial Intelligence has been a buzzword in the technology industry for quite some time. It is a rapidly growing field that has the potential to transform multiple industries, including mechanical engineering. The integration of AI in mechanical engineering has opened up new avenues for innovation and research, providing engineers with the tools to design, develop and produce machines that can operate with high precision and efficiency.

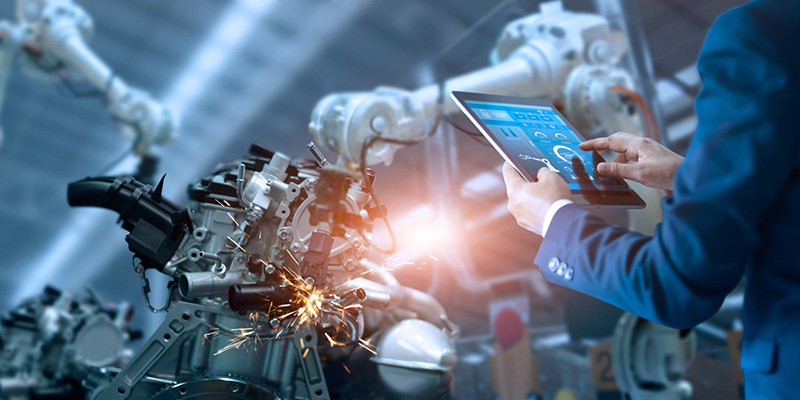

One of the primary benefits of AI in mechanical engineering is the ability to create smart machines that can learn and adapt to new situations. With the help of AI algorithms, machines can process large amounts of data, make informed decisions and carry out complex tasks without human intervention. This has resulted in the development of intelligent systems that can operate autonomously, improving the efficiency and accuracy of mechanical engineering processes.

In the manufacturing industry, AI has been used to optimize production processes, increase quality control and reduce wastage. Intelligent machines can monitor and adjust their performance in real-time, allowing for continuous improvements in production processes. For example, a company called Flex, used AI to develop a new robotic assembly line for building products. The robotic assembly line uses AI algorithms to monitor the production process, detect defects and make adjustments in real-time, significantly reducing errors and improving efficiency. One area where AI is particularly useful is in predictive maintenance. Predictive maintenance involves the use of data and machine learning algorithms to predict when a machine is likely to fail, allowing maintenance to be scheduled before a failure occurs. This approach can prevent costly downtime and reduce the need for reactive maintenance. AI can also be used to optimize the design of mechanical systems. Machine learning algorithms can analyze large amounts of data to identify patterns and make predictions about how different design choices will affect system performance. This can lead to more efficient and cost-effective designs. Another area of research is the development of intelligent energy systems. Engineers are exploring the use of AI to optimize energy production and consumption, reducing the environmental impact of energy usage. For example, AI algorithms can be used to control wind turbines, ensuring that they operate at peak efficiency and minimizing downtime

In addition to manufacturing, AI is also being used in the design and development of new products in mechanical engineering. Engineers can use AI algorithms to generate and evaluate thousands of design concepts in a fraction of the time it would take to do so manually. This has resulted in the development of more efficient and sustainable products, such as wind turbines and electric vehicles. In the future, the integration of AI and mechanical engineering is likely to continue to expand. One of the most promising areas of research is the development of self-healing materials. Engineers are developing materials that can sense damage and automatically repair themselves using AI algorithms. In conclusion, the integration of AI and mechanical engineering has had a significant impact on multiple industries. As such, it is essential for engineers to stay up to date with the latest developments in AI technology and incorporate them into their designs and processes to remain competitive in the industry. However, there are also concerns about the impact of AI on the job market. As AI-powered machines become more advanced, they may be able to replace human workers in certain industries. This could lead to job losses and social upheaval if adequate measures are not taken to prepare workers for the transition to a more automated workforce.