Zain Hasnain, Mechanical Engineer

zainusyed313@gmail.com | linkedin.com/in/zain-abbas-hasnain

Abstract

Additive manufacturing and 3D printing have emerged as disruptive technologies,

revolutionizing the manufacturing industry worldwide. This article provides an overview of the

recent advancements in additive manufacturing. Additionally, it discusses how industries in

Pakistan, particularly in the pharmaceutical and power generation sectors, can harness the

potential of these technologies to improve efficiency, reduce costs, and drive innovation.

Introduction

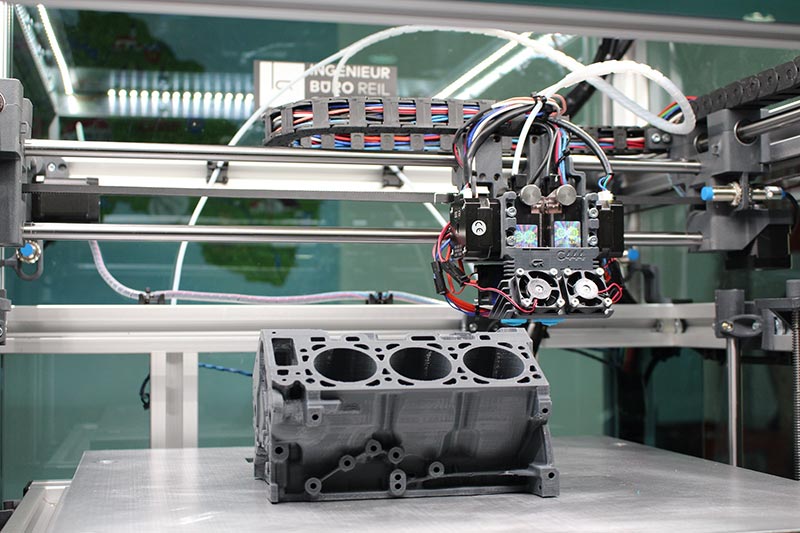

Additive manufacturing, often referred to as 3D printing, has redefined the way products are

designed, prototyped, and manufactured. In contrast, additive manufacturing builds objects

layer by layer, enabling unprecedented design flexibility and customization. As a result,

industries around the world are increasingly adopting 3D printing technologies to improve

prototyping, production, and supply chain efficiency.

Advancements in Additive Manufacturing

- Materials Diversity

One of the significant advancements in additive manufacturing is the increased range of

materials available for 3D printing. Initially, 3D printing was limited to plastics, but it has now

expanded to metals, ceramics, and composites. As of 2021, over 50 different types of materials

could be used in 3D printing, ranging from plastics to metals and ceramics. - Speed and Accuracy

Advances in printer technology have significantly improved the speed and accuracy of 3D

printing. High-speed printers, with improved precision, enable rapid production of complex

components with tight tolerances. This is particularly valuable in sectors where precision and

speed are critical, such as automotive and electronics manufacturing.

High-speed 3D printers, such as the Carbon M2, can print at speeds of up to 20 times faster

than traditional 3D printers. - Mass Customization

3D printing allows for mass customization with ease. Mass customization enables companies to

cater to individual customer preferences while maintaining the efficiency of mass production.

According to a Deloitte survey, 91% of consumers expressed interest in customized products,

and 1 in 5 was willing to pay a 20% premium for such items. - Reduced Waste

Additive manufacturing is inherently more sustainable than traditional manufacturing methods.

By building products layer by layer, 3D printing minimizes material waste. This is not only

environmentally friendly but also cost-effective. Traditional manufacturing methods can

generate up to 30% waste material, whereas 3D printing typically produces less than 5% waste.

Applications in the Pharmaceutical Sector

The pharmaceutical industry in Pakistan can benefit significantly from additive manufacturing.

Here are some potential applications:

- Customized Medications

3D printing can produce personalized medications with specific dosages and release profiles.

This enables the pharmaceutical sector to address individual patient needs effectively. This

could be especially beneficial in managing chronic diseases and improving patient adherence.

The FDA approved the first 3D-printed medication, Spritam, in 2015. It dissolves faster than

traditional pills and can contain precise dosages. - Prototyping Drug Delivery Systems

Additive manufacturing can accelerate the prototyping of drug delivery systems, such as

inhalers or transdermal patches. This technology allows pharmaceutical companies to test

various designs quickly, reducing time to market.

Applications in the Power Generation Sector

The power generation sector in Pakistan can leverage additive manufacturing in several ways:

- Customized Turbine Components

Power plants can utilize 3D printing to create customized turbine components, such as blades,

with improved efficiency. This can lead to increased power generation and reduced

maintenance costs. GE successfully 3D-printed a functioning jet engine, demonstrating the

capabilities of 3D printing for highly customized, efficient components. - Rapid Prototyping for Energy Storage

Additive manufacturing allows for the rapid prototyping of energy storage systems, such as

batteries and capacitors. This accelerates innovation in renewable energy and grid stabilization.

Tesla used 3D printing for rapid prototyping of components in their energy storage products,

helping to bring products to market faster. - Maintenance and Spare Parts

3D printing can be used to produce spare parts for aging power generation equipment. This

reduces downtime, extends the operational life of existing infrastructure, and saves on

replacement costs. Siemens Energy used 3D printing to manufacture replacement components

for gas turbines, reducing lead times from months to days

Conclusion

In Pakistan, the pharmaceutical and power generation sectors can capitalize on these

advancements to enhance their operational efficiency, reduce costs, and drive innovation. The

implementation of 3D printing in these sectors requires careful consideration of regulatory,

quality, and safety standards.