A wide range of new and used generators and engines are available to potential buyers in the market today. The buying cycle typically starts out with identifying a need (i.e. to power heavy equipment, provide emergency backup, prime or standby power, etc.), then performing research and analysis to determine what your specifications and requirements are. After that, you are usually faced with the all-important decision of whether to go with a new or used engine and/or generator. In order to reach an educated decision and an answer to that, a number of factors must be taken into account, many of which are listed throughout this article.

New Generators

Just as it is when purchasing a new car, the number one reason for buying a new generator is the fact that it comes with a standard manufacturer’s warranty. The length and terms of each warranty varies greatly but is typically between one and two years, depending on the intended usage of the generator and/or engine. However, as it is with cars as well, those warranties do not come without a substantial increase in cost. And, depending on the size, make and manufacturer, there may be a long wait time or limited availability so extra time is often required to account for that, especially on the larger generators. For companies who have the time to wait and really want the security a warranty offers for a year or two, new generators can be the best way to go. As it is with any heavy equipment, you simply need to weigh all the pros and cons of your particular situation to determine what the best option is for your needs.

Used Generators

While they do not usually come with a warranty, it is often extremely advantageous to buy rebuilt diesel engines and used electric power generators for a number of reasons. A key one is of course that used generators with low hours on the engines are often available at very attractive prices, and are substantially below the high retail prices of new units. It’s even possible to save up to 50% or more by getting a low-hour used generator instead of a new one.

Another key benefit to purchasing a used genset is the fact that they are readily available and can be bought and installed very quickly. There is no waiting because of limited availability and factory lead times, you simply buy it and have it shipped right then and there. Many sellers will even include shipping in the cost of the unit.

Also, because most name brand manufacturers build industrial strength equipment, the risk is negligible. Power generators are built to last and work whenever necessary, as that is their true function in most cases, to always be there when you need them most (as in an outage). And, depending on the age of the unit, it may even still come with a warranty, or at least a guarantee of some type from the dealer. Whenever possible, finding a generator that was previously only used for emergency backup or standby power is the way to go. Backup generators are only run when the prime power goes down so many of these are hardly used at all and have a long maintenance free life ahead of them still.

The only real disadvantage of purchasing a used generator is just that, it was owned and used by someone else. Therefore, you most likely have to go on the word of the seller as to the previous usage, history, and current condition the generator and engine are in. This is why it’s important you always consider purchasing from a reputable company who has the technical expertise and infrastructure to properly test, repair and/or rebuild these large industrial machines. Most established sellers will test all their used generators for various loads, but many small brokers and individuals simply do not have the appropriate resources at their disposal. Testing and servicing are both obviously critical. Most tests often come with a verification certificate that details each units functioning. Low-hour used diesel generators ranging in size from 35 kW to 2 MW are often readily available. Low-hour indicates that the generator has been in operation for a reasonably low number of hours. Prices obviously vary greatly based on the kW, HP, hours, manufacturer, KVA, etc., and range anywhere from, $16,000 to $800,000 or more.

Surplus Generators

Surplus machinery is basically new equipment that has been in inventory for a long time or exceeds the original requirement of the purchaser and is not being utilized. Pre-owned surplus generators are sometimes sold by individual companies, auctions, distributors, dealers, and even the military. Companies often sell the surplus to liquidate their excess and/or unused inventory and turn the assets back into cash. As an example, if a company receives fifteen 200kW generators in a bulk deal, and the requirement was only for ten generators, then the five surplus units are most likely going to be sold since they do not need the extra units. If you can obtain a surplus generator at a reasonable price, they are often one of the best and smartest buys you can make. The only downside to purchasing surplus equipment is that sometimes the price is still very close to the original new list price, and if money is a key issue, you could probably save even more by going with a standard low-hour used genset instead.

Generator Ends

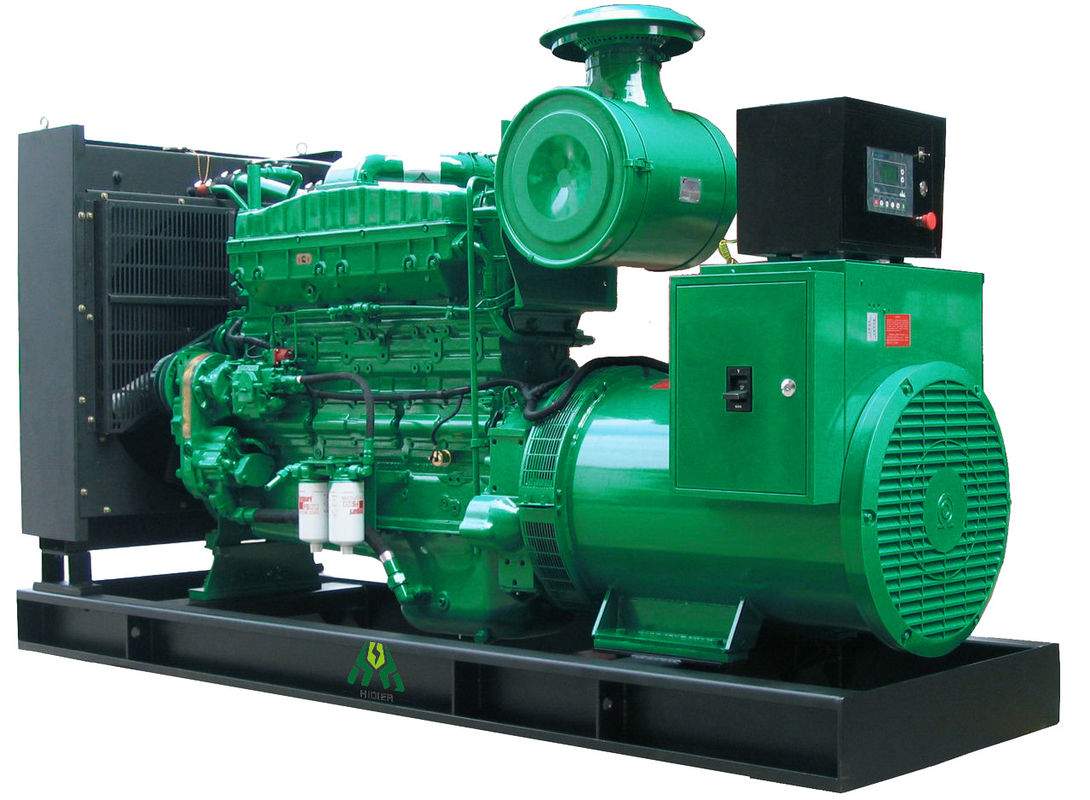

Generator ends are the points which determine the smoothness of the voltage that is available from the generator. These are basically the end points of the generator. The ends play the most important role in voltage regulation. The effectiveness of generator ends becomes more important in cases where sensitive electronic equipment is used, such as computers. Used generator ends are available for all specifications. As usual, you can lower your costs by choosing used generator ends over new ones. For reference, the diesel engine and generator ends make up what is referred to as the generator set.

Rebuilt Diesel Engines

Yet another option to consider when buying an industrial engine or generator set is whether or not to consider a rebuilt diesel engine. Rebuilt engines go through a rigorous process that ultimately produces a like-new product in most instances and can be one of the most cost-effective ways of saving money on your investment. To give you an idea of what rebuilding routinely entails, some key steps are listed below:

While rebuilding engines, engine cores are completely disassembled and all parts are cleaned in a chemical vat. Engine parts are sent out for testing, inspection and rebuilding. This whole procedure is extremely elaborate and involved.

Cylinder blocks are also checked for surface cracks. Cylinder bores, counter bores and crank bores are checked and repaired if needed. Water passages of the cylinder blocks are pressure tested. These crankshafts are then are measured and polished or machine ground to standard manufacturer specifications.

Connecting rods and blowers are replaced or remanufactured. Water pumps and fuel pumps are remanufactured using new bearings, seals and shafts. Other subassemblies and parts are also remanufactured to strict factory standards and specifications. Prior to the release, fuel pumps are also bench tested.

The engines are reassembled using all new bearings, seals, gaskets and numerous new consumable parts. Complete engines are tested for various loads on an advanced dynamometer. Horsepower output, rpm, oil pressure, crankcase pressure and air box pressures are recorded along with engine specifications and supplied with a startup inspection report. Engines are then rust proofed and weatherproofed with a red oxide layer or with enamel paint.

Complete care is taken to ensure that the rebuilt engine is literally almost as good as new when the process is finished. This is why it is often a great idea to seriously consider purchasing a rebuilt diesel engine for most applications. The only real downside to the process is that you need to make sure the seller is a trustworthy and professional source who has the technical expertise and personnel to properly perform this process and handle all the meticulous details. Of course, here at Diesel Service and Supply we have some of the industry’s top diesel technicians and have been rebuilding diesel engines for over 23 years.

New vs. Used – Summary

In summary, as you can see, it is obvious that a used, rebuilt, or surplus generator and/or engine can typically provide much more value for your money and should therefore always be a consideration. However, as it is with any large industrial/commercial purchase, there are a number of factors to consider and weigh before making your final choice.