Technical Article – Written By: Zeeshan Ahmed Siddiqui, P.E.

INTRODUCTION

As the demand for air conditioning units continues to rise due to increasingly hot and humid climates, and amidst growing discussions on global warming and climate change. Besides, consumers are also facing the challenge of high electricity costs. In response, there is a growing preference for energy- efficient air conditioning equipment. R32 refrigerants, with their low Global Warming Potential, are becoming widely used in small air conditioning units. However, some cases reported that R32 units’ blast and causes injury / death and property.

This article covers essential aspects of R32 refrigerants, from fundamental concepts to detailed discussions on GWP, applications, thermal properties, and causes of leakages and bursts, as well as safety considerations for both design and installation procedures.

DEFINE R32, LOW GWP, HIGH EFFICIENCY, SAFETY

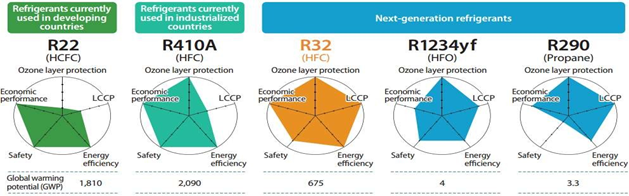

Please see the below pictures to understand better R32 compared to HCFC, HFC and New Refrigerants:

-32 is mildly flammable compared to gases like R410A & R22. This means that extra precautions will be taken during design and installation.

CAUSES OF SYSTEM BURST

Here are some key reasons for a burst in air-conditioning systems using R32:

- Inadequate design and location of indoor & outdoor units.

- For High Ambient cities / countries – in case of placement of outdoor units at direct Solar’s exposure.

- Low thickness / gauges piping or inappropriate fittings.

- Improper vacuum and have oxygen in the system.

- Uses low quality of electrical appliances, bypass electrical safeties and joints of wire.

- No proper ventilation for outdoor / indoor units.

- Install indoor units in a small, packed room and without ventilation.

- In case of leakage indoor by any means, R-32 is heavier than air and accumulate at low ground level (concentrated), having low velocity and any open flame or find any source of ignition.

- Physical damage to the system, such as impacts or punctures, can compromise the integrity of the refrigerant lines.

ENSURE SAFETY DESIGN & INSTALLATION:

If you install an R32 system in your home, make sure that your installer uses certified R32 accessories like pipe and parts to avoid damage to your air conditioner.

- Proper design and location of indoor and outdoor units and piping routes.

- Call authorized companies / personnels for supply, installation and maintenance.

- For high ambient countries, install outdoor under shaded areas to avoid very high condensing pressure and proper ventilation may avoid damage.

- Thickness of copper pipes for R32 should be more than 0.8mm. Never use low quality copper pipe and fitting.

- During installation, install the refrigerant piping properly before running the compressor.

- Operation of compressor without fixing refrigeration piping and valves at opened position will cause suck-in of air, abnormal high pressure in refrigeration cycle and result in explosion / injury.

- For electrical work, follow the national regulation, legislation and manufacturer’s guidelines.

- Do not use joint cable for indoor / outdoor connection cable.

- Be sure to comply power supply and connecting cable for size and wiring method.

- After completion of installation, confirm there is no leakage of refrigerant gas.

- Evacuate the air properly in the connecting pipes and in the indoor unit using a vacuum pump.

- Vacuum pump should be rated with A2L flammable refrigerant.

- Ventilate, if there is refrigerant gas leakage during operation. It may cause toxic gas when the refrigerant contacts with fire.

- In case gas leaks, accumulates at surrounding of the unit and get the source of open flames or ignition then it may cause fire.

- Overcharge may cause over current and damage to compressor.

- Personal Protective Equipment should always be worn when handling R32.

CONCLUSION

In summary, R32 has a higher energy efficiency ratio (EER), a lower global warming potential, pure refrigerant, zero ODP, flammability class A2L (according to ASHRAE Standard 34), operates at higher pressures. R32 and R410A are similar in some ways but they aren’t interchangeable. Mixing of old and new refrigerants and using old piping system can result in dangerous chemical processes and damage to the HVAC system. Do not vent gases into the atmosphere directly.

Install outdoor units at shaded and ventilated areas. To use of extract fans while charging, particularly if the outdoor unit is used in an enclosed area. Works shall be undertaken under a controlled procedure define above to minimise the risk of a flammable gas.

If an air conditioner indoor unit is installed in a small room, then have ventilation system. So that if the refrigerant accidentally leaks out, its concentration does not reach or exceed the limit. In case of ventilations in occupied spaces shall be checked to confirm no obstruction.

Proper vacuum is a key. R32 refrigerant poses a potential risk of suffocation, if its concentration should rise excessively. Ensuring that the gas is not exposed to open flames or any ignition sources.

R32 represents a significant advancement in refrigerant technology, offering notable environmental benefits and energy efficiency improvements. While it does present certain risks, proper system design, handling, labelling, and maintenance can effectively manage these risks.

Prior buying and beginning work on new refrigerant air-conditioning systems containing flammable refrigerants, follow proper design, installation and safety checks to ensure that the risk of ignition is minimised.

I urge all stakeholders to familiarize themselves with the fundamental information about R32 refrigerants to ensure their safety and prevent any potential accidents or property damage. Immediate actions must be taken from now to guarantee future-proof solutions to all!!!