Providing Energy Saving Products and Solutions for Compressed Air Systems in Pakistan

Amid global energy crises that is hitting nearly every sector including industries, hospitality, healthcare, Governments etc., we all are needed to lessen the irresponsible use of energy to reduce our carbon footprint and its impact on the overall ecological balance.

If we talk particularly about the industrial sector, the overall increase in energy prices is pushing industries more towards adopting smart energy saving strategies as a part of their overall business efficiency programmes. Not only does it help with cost savings in the production/manufacturing, but also a crucial step towards more green and clean environment.

In this regard, SMC Corporation Japan, the Global Leader in Pneumatics, has developed some of the most innovative ranges of energy saving products and solutions for compressed air systems in industries.

How much air is being wasted in compressed air systems used in Pakistan?

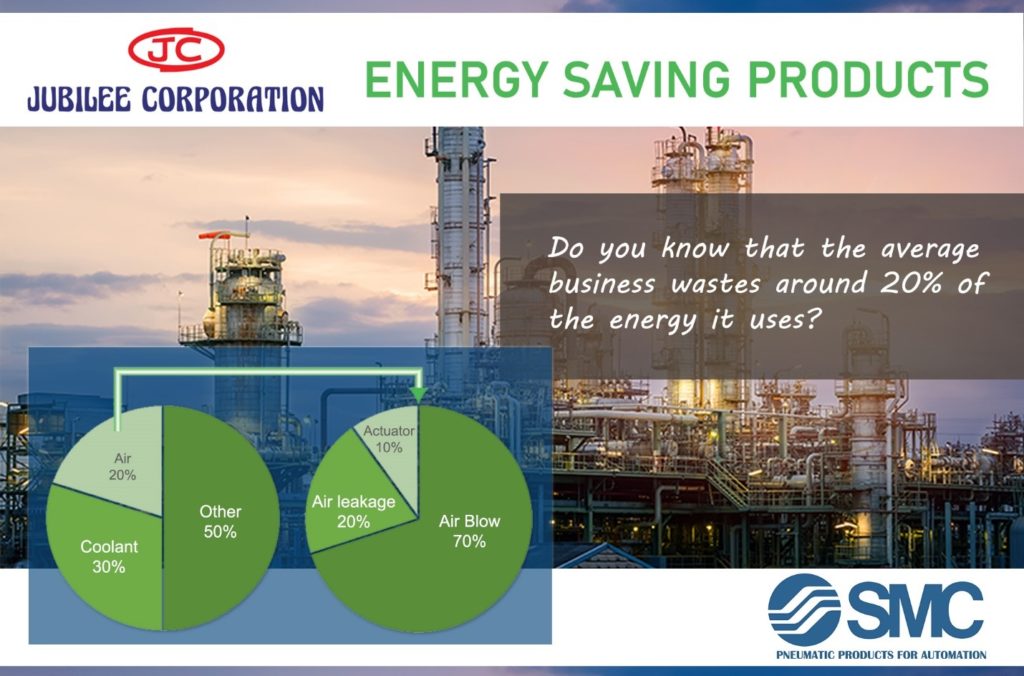

The electrical energy required to manufacture compressed air for production facilities account for around 20% of the total industrial consumption. In an average facility, 70% of the generated compressed air is used in air blow applications, 10% for actuation with the remaining 20% is lost through leakages.

Most compressed air users are unaware that their systems often offer poor energy efficiency and that by focusing on these systems alone, energy saving can be made between 5 to 30%.

Effective ways to achieve efficient Compressed Air System

- Reduce the air pressure to the optimum requirement

- Size the pneumatic components for the actual performance needs

- Filter and dry air in an appropriate way

- Use only quality products

- Isolate the plant when idle using valves

- Stop air blow when not needed

- Generate vacuum using multi-stage ejectors with vacuum switches

- Where possible select low energy consumption components

- Periodically check the air consumption

- Prevent and reduce air leaks

- Use Nozzles and Air Guns for air blow.

In Pakistan, Jubilee Corporation (JC) has been SMC’s authorized distributor for last 40 years. Together, Jubilee Corporation and SMC are working with a wide array of industries including automobile, food and beverages, sugar, packaging, home appliances, textile, cement and pharmaceuticals.

JC’s dedicated team of engineers work hand-in-hand with technical personnel in the industries to provide customized solutions for compressed air to achieve maximum energy savings.

The evaluation of energy saving process involves monitoring of current energy consumption, find leakages and work on improvement opportunities. Once the system is thoroughly checked from top to bottom, the energy saving experts provide a comprehensive evaluation for the whole compressed air system. This includes analysis of the existing compressed air system, share measurements, findings, improvement proposals, expected savings and system maintenance recommendations.

If you’re interested in hearing more about SMC’s Energy Saving products and solutions, you can reach us at [email protected].