By Zeeshan Ahmed Siddiqui, PE.

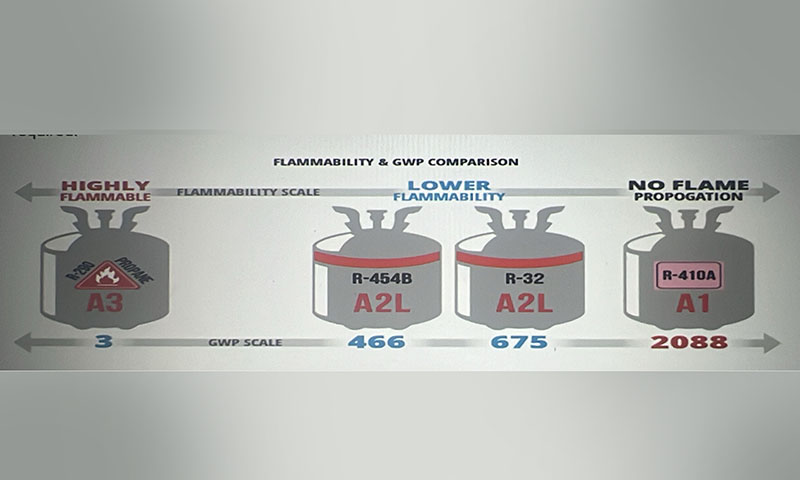

The purpose of this technical article is to understand the importance of new available refrigerants, and their applications. In this paper, focus will be on the low or ultra-low GWP refrigerants like hydro-fluor olefins HFO / HFO blends, HC, Natural Refrigerants are environmentally friendly next generation refrigerants. A2L refrigerants are slightly flammable than A2 and A3 is highly flammable. B1 & B2 represents toxicity. Mostly new refrigerants belong to A2L, we should have a serious look at design and installation. Technicians need to take the relevant safety measures for the correct transport, storage and handling of flammable gas. R-32 GWP of R32 is 675 while R-410 has 2,088 GWP. EPA based on Kigali amendment bans CFCs with GWP above 700; this stops new production or importation of R-410a Units by Jan 01, 2025. Besides, R-32 is a colorless and odorless, mildly flammable gas (A2L).

R-452B / R-454B R452B is a mixture of HFC and HFO, with a glide temperature of 1.2 K. Its GWP is 676. Further, R452B has a safety classification of A2L and lower saturation pressure than R410A and R32. R454B has 466 GWP compared to R-410 has 2,088 GWP. R-454B is mildly flammable gas (A2L) and colorless. Many manufacturers are using R454B refrigerant. It provides easy conversion with minimal changes from R-410a design. Like R-410A, R-454B is a near azeotrope and so has minimal glide. R-513A R513A is a medium pressure, non-flammable. The GWP of R-514A is 573. They have been assigned an A1 safety classification under ASHRAE 34. It may be an alternative to R-410a for new medium and high temperature systems. It may use in screw and centrifugal chillers. It is a direct drop-in replacement for R-134a in existing commercial and industrial medium and high temperature refrigeration equipment that uses positive displacement compressors and direct expansion systems. R-514A ASHRAE 34 classes as a B1 category refrigerant, meaning that it is not flammable. It has a low pressure, non-ozone depleting, low global warming potential (GWP) hydrofluoroolefin (HFO) based replacement for R-123. It is suitable for new and retrofit systems, offering an optimal balance of properties, including high energy efficiency and environmental sustainability.

R-1234ze is known as a “next-gen” refrigerant & classified as HFO. It has category is A2L and not design for retrofit projects. While the fact R1234ze has ultra-low value GWP value is 1 vs 1300 of the R134a, it also results in very efficient chiller operations. The application is air cooled and water-cooled screw chillers as well as water cooled centrifugal chillers. Besides, it can be used in medium temperature commercial refrigeration and heat pumps. This refrigerant has a future choice within a stringent environmental regulation. R-1233zd is known as a “next-gen” refrigerant & classified as HFO. It has ultra-low value GWP value is 1. R1233zd is an ideal for low pressure centrifugal chillers which are common in cooling systems for large buildings. Besides, it has no temperature glide. Refrigerant R1233zd(E) is classified as a fully safe refrigerant (ASHRAE Class A1).

R-1233zd is a new and widely accepted refrigerant for high-capacity mainly centrifugal chillers for its attractive properties and mainly replace R123 refrigerant. Total Life Cycle Cost of a system has become increasingly important in recent years as the cost of the system to acquire, install, operational cost, and maintain gained focus.

CONCLUSION: Designing to New Standards: • Hydrocarbons require relatively low energy levels to ignite. So, use smaller equipment. • Minimum Ignition Energy – MIEs of A2Ls are much higher than hydrocarbons. • Many potential ignition sources for hydrocarbons (e.g., static spark) will not ignite A2Ls. • Follow ASHRAE Standard or Local Codes for all refrigerants and especially A2L and A3 categories. Safety Features: • Handling, storage and transportation of refrigerants should be as per defined as per Safety Data Sheet of Manufacturers. • Personal Protective Equipment (PPE) must be used prior any operation. • Leak Detectors shall activate according to the defined timeline of standards.

Purge systems and relief devices must be vented outside. • Self-closing doors & Labeling & Marking. • Follow the phase down timeline of 2016 HFC Kigali Amendment. • Leakage of refrigerants is considered as direct emissions. • Indirect emissions mean emission of Carbon dioxide because of inefficient equipment. • Proposed GWP limit is 150, 300 and 700 depends on different applications such as Motor Vehicle, Residential Equipment, Commercial Buildings, Industries and Cold Storages etc. • It should be noted that the Kigali agreement is a phase-down and not a phase-out.

• Life Cycle Climate Performance is an evolving method to evaluate the carbon footprint and global warming impact of heating, ventilation, air conditioning, refrigeration systems, and potentially other applications such as thermal insulating foam. It is calculated as the sum of direct, indirect, and embodied greenhouse gas emissions generated over the lifetime of the system i.e. from manufacture to disposal. • Natural Refrigerants, HCs and HFOs are better choices for long term replacement. A2L refrigerants are rated as having low flammability potential. When handled correctly, using the proper equipment and tools, A2L refrigerants are safe and reliable.

• Immediate reductions in greenhouse gas emissions are the only way to stop global temperatures increments and disasters of climate change.

• Great things in business are never done by one person. They’re done by a team of people By Steve Jobs.